TECHNOLOGY

INSULATION SYSTEM IN TRUE CLASS H+

The medium and high voltage X-Type alternator series is equipped with the latest technologies in terms of insulation. Mecc Alte Power Products is a pioneer in the development of the true class H+ insulation system and we are proud that this technology is now accepted as a worldwide industry standard.

Our HVi insulation system for medium and high voltage generators is developed in collaboration with Von Roll, world leader in materials and processes for high voltage alternators.

The insulation system is based on epoxy resin in class H, with low viscosity, without emission of volatile organic compounds (VOC), in combination with Mica insulating tapes and mechanical protection with fiberglass, able to guarantee a insulation voltage up to 15.75kV.

We have implemented the best technology available on the market for high temperature and high vibration applications. This allows us to maintain excellent levels of quality and reliability in various industry sectors, from Oil & Gas to the genset world, passing through marine applications and heavy industry.

We can summarize the features that make this technology at the vanguard in various sectors in:

- Excellent behaviour at high temperatures: performance is maintained even after aging;

- Excellent mechanical properties of flexibility and strength, suitable for high vibrations;

- Good thermal conductivity;

- Good electrical properties;

Mecc Alte HVi insulation system complies with the European REACH regulation and it is approved by API (American Petroleum Institute) for particularly polluted and harsh environments.

The dedication that Mecc Alte has placed, in recent years, in the development of the insulation system has led to excellent results. The reliability and resistance that have been achieved have allowed us to extend the warranty to 4 years for all the medium and high voltage parts of the X-Type series alternators.

The HVi insulation system is the cornerstone of the PROTEXPLUS protection system, implemented on the X-Type series.

TEST PROCEDURE

Mecc Alte HVi insulation system has been tested according to the strictest procedures dictated by the IEC 60034-18-31 standard and IEEE 1776, for 18 months, in Von Roll laboratories in Switzerland.

The test consisted in subjecting several samples to aging cycles of different duration at high temperature, between 200°C and 240°C, until breakage. Each sample, made up of 5 copper bars insulated according to Mecc Alte HVi insulation system, was inserted inside a model that reproduces the alternator stator slots. After each thermal test cycle, the under-examination sample was subjected to a series of tests on a vibrating table, tests in a high-humidity climatic chamber and high voltage insulation tests of turn-to-turn and main wall insulation.

TESTS RESULT

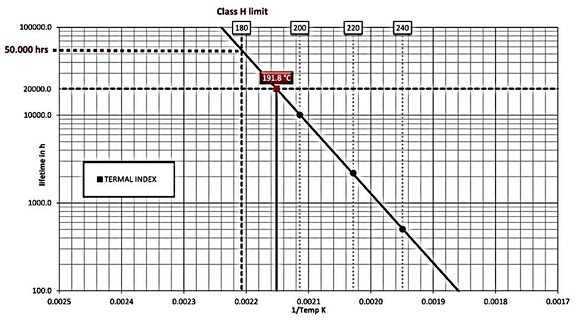

The main target of the tests is to define a thermal index of the insulation system. Standards state that the thermal index is equivalent to the maximum temperature to which the insulation can be subjected for 20.000h without undergoing breakdown.

The results of the tests allowed us to define, according to Standards, a thermal index of 191.8 ° C, way higher than Class H, which corresponds to a thermal index of 180°C. Therefore, the alternator can operate continuously for 20,000 hours, at a temperature of 191.8°C, without being damaged.

This leads to the conclusion that the medium-high voltage Mecc Alte X-Type series alternators can work in continuous operation (PRP) at temperature Class H for more than 50.000h without suffering damage. Thanks to the thermal index higher than 180°C, the life expectancy of one of our Class H/H alternators is higher than a classic F/F system. If we consider an H/F system, the machine life cycle extends to more than 300,000h, 15 times higher.

In addition to improving the life expectancy of the alternator, insulation in Class H/H allows a more compact solution (possible lower axle height and consequent economic impact), therefore with a greater power density, compared to the classic solution of alternators in Class F/F.

To increase the alternator strength and life, a protective layer (epoxy red enamel), suitable for high temperatures, can be applied on the stator and rotor windings – on stator as standard and standard or optional, depending on the model, on rotor - which guarantees extra protection to the machine in the case of installations in particularly polluted and aggressive conditions such as marine environments.

VIBRATIONAL ANALYSIS, OPERATIONAL DEFLECTION SHAPE & MODAL ANALYSIS

If the insulation system is a fundamental aspect in the construction of the alternator, vibrations are not less important. Especially in applications such as generating sets or in heavy industry, the alternator is subject to considerable external stresses.

At Mecc Alte, it is our responsibility to monitor, plan and act to minimize harmful vibrations on alternators. Therefore, in the process of designing these types of machines, it is essential to perform vibrational analysis.

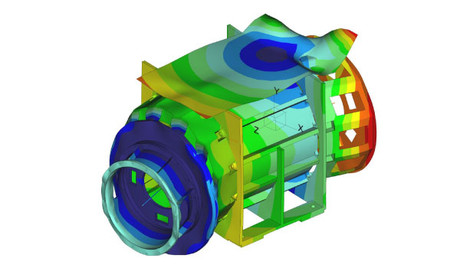

This goal is achieved by performing ODS (Operating Deflection Shape Analysis) or modal analysis:

- ODS analysis shows the deformation of a structure at a specific frequency and shows the response of a structure to both resonant and forced vibrations, and is generally very representative of real-world data.

- the modal analysis is similar to the ODS. It is possible to visualize the deformation of the structure, but mainly concerns the resonance frequencies (or natural frequencies) of the structure.

Mecc Alte has developed projects, together with strategic partners, for a in-depth study of vibration propagation in genset applications, therefore between diesel engine and alternator. One of these projects was to confirm / improve the mechanical design of the ECO49 family of the X-Type series.

The project developed through the following phases:

- acquisition of ODS in a real MTU 20V4000G63 / Mecc Alte ECO 49MV-L generator set. The vibrations were measured through 8 three-axis accelerometers in 12 different points, during the commissioning of the group genset. In total, 288 different tracks were collected on the machine frame and 306 tracks on the alternator feet, at 0%, 75% and 100% of the active load;

- the ECO49MV-L was simulated with an FEM software to model the modal parameters: natural frequencies, modal damping and shape;

- through a curve adaptation process a simplified virtual model of the engine was created;

- finally, the ultimate goal of the project, a virtual test bench has been created, to estimate the vibrations to which the alternator is subjected in different operating conditions even with different types of engine.

This virtual test bench is now an important tool used both in the development of new machine families, such as the most recent ECO47 of the X-Type series, and the improvement of components such as terminal box or shields.

To learn more about the innovative technology that goes into our x-type range, please don’t hesitate to get in touch with a member of our expert alternator product support team and find the perfect solution to your company's requirements.